Kitchen cabinets define the look and functionality of a space, but material choice influences durability, maintenance, and cost. Wood has long been a preferred option, but engineered materials like Medium-Density Fiberboard (MDF) have become popular for their affordability and smooth finish.

This guide breaks down how MDF compares to wood, highlighting its advantages, limitations, lifespan, and maintenance needs. Whether you’re planning a kitchen remodel or evaluating its pros and cons, knowing the properties of MDF will help you make the right choice.

What is MDF?

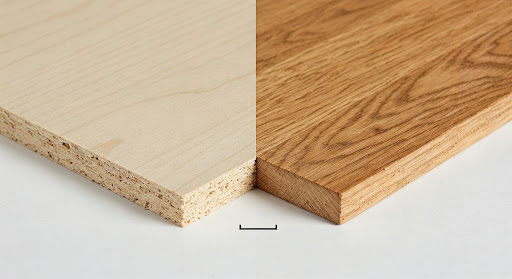

Medium-Density Fiberboard (MDF) is an engineered wood product made from wood fibers, wax, and resin, compressed under high heat and pressure to form dense, uniform panels. The process starts with breaking down hardwood or softwood residuals into fine fibers, which are then dried, blended with adhesives, and shaped into boards using extreme pressure and temperature. This composition creates a smooth, stable surface without the knots or grain patterns found in natural wood.

Manufacturers use MDF for cabinet doors, shelving, and furniture panels because of its versatility and ease of customization. The absence of grain allows for a flawless surface, making it one of the best kitchen cabinet materials for painted finishes.

Different Types of MDF and Their Applications

Manufacturers produce MDF in various forms to meet specific design, durability, and functional requirements. While standard MDF serves as a versatile material for cabinetry and furniture, specialty MDF types enhance performance in different applications.

General MDF Types

- Standard MDF works well for furniture, cabinet doors, and decorative panels. Its smooth surface provides an ideal base for painting or veneering. Because it lacks moisture resistance, it performs best in dry indoor environments where exposure to water is minimal.

- Moisture-Resistant MDF (MR-MDF) contains water-repellent resins, making it suitable for kitchens, bathrooms, and other humid spaces. Manufacturers typically dye it green to distinguish it from standard MDF. While it resists moisture better than regular MDF, prolonged water exposure can still cause swelling.

- Fire-Retardant MDF (FR-MDF) includes flame-resistant chemicals to slow combustion. Builders use it in commercial settings, public buildings, and areas requiring enhanced fire safety. It’s often red or blue to differentiate it from other MDF types.

- High-Density MDF (HDF) has a more compact fiber structure, making it stronger and heavier than standard MDF. It holds screws better and withstands frequent use, making it ideal for flooring, countertops, and high-traffic furniture.

- Lightweight MDF is a lower-density option used for applications where weight matters, such as interior panels, display units, and decorative molding. While easier to handle, it is less durable than other MDF types.

Specialty MDF Types

- Beadboard MDF features vertical grooves that resemble traditional tongue-and-groove paneling. It is commonly used for wall paneling, wainscoting, and decorative cabinet doors, providing a classic aesthetic without the complexity of real wood planks.

- Slatwall MDF includes pre-cut horizontal grooves designed to hold brackets and hooks. It is common in retail displays, garage storage systems, and commercial shelving, where adjustable configurations are needed.

- Ultralite MDF weighs less than standard MDF, making it easier to handle and install. It is commonly used for furniture components, trade show exhibits, and ceiling panels, where reducing weight is essential.

- Bendy MDF (Flexible MDF) has a thinner core that allows it to bend into curves. It is ideal for rounded cabinetry, curved reception desks, and arched doorways, where standard rigid MDF would not work. Once shaped, it can be laminated or painted.

- Melamine MDF has a melamine-coated surface that resists scratches, stains, and moisture. It is ideal for kitchen cabinets, ready-to-assemble furniture, and shelving, offering a durable, easy-to-clean finish.

- Prelaminated MDF comes with a factory-applied laminate layer, providing a finished surface without additional coatings. It is used for office furniture, wardrobe panels, and modular kitchen units, where quick installation and a polished look are priorities.

- HMR MDF (Highly Moisture-Resistant MDF) offers superior resistance to humidity and water exposure. This type is best suited for bathroom vanities, outdoor furniture, and laundry rooms, where prolonged moisture contact is a concern.

- Veneered MDF combines the affordability of MDF with a natural wood veneer finish, delivering the look of real wood at a lower cost. It is commonly used for high-end cabinetry, wall paneling, and custom furniture, where wood grain aesthetics are desired.

MDF vs. Solid Wood Cabinets

MDF does not expand or contract with humidity changes, making it more stable than solid wood in fluctuating environments. However, it absorbs water quickly if exposed to moisture, leading to swelling and deterioration. Standard MDF lacks the strength of natural wood and can crack under heavy impact, but it allows for intricate designs without visible grain.

Moisture-resistant MDF offers better durability in humid spaces but remains susceptible to prolonged water exposure. MDF is also significantly more affordable than solid wood, making it a budget-friendly option for homeowners prioritizing a clean, painted aesthetic. Its smooth surface makes it an excellent choice for two-toned cabinets, allowing for seamless color transitions between upper and lower cabinetry or contrasting door and frame combinations.

Solid wood cabinets are crafted from natural hardwoods like oak, maple, or cherry. The material provides superior durability and can withstand daily wear, making it a long-term investment. Unlike MDF, solid wood can be refinished multiple times, extending its lifespan.

While solid wood expands and contracts with temperature and humidity changes, proper sealing and finishing help minimize warping. It naturally resists minor impacts and holds screws more securely than MDF, ensuring structural integrity over time.

Wood also showcases natural grain patterns, making it the preferred choice for stained finishes. Although more expensive, solid wood cabinets increase home value and last for decades with proper maintenance.

Pros and Cons of Using MDF Kitchen Cabinets

MDF is a popular material for kitchen cabinets due to its affordability and smooth finish. While it offers benefits in cost and customization, it also has limitations in durability and moisture resistance. Below is a breakdown of its pros and cons.

| ✅ Advantages | ❌ Disadvantages |

| Affordable – Costs significantly less than solid wood and many plywood options. | Prone to water damage – Absorbs moisture easily if not sealed properly. |

| Smooth surface – No wood grain, making it ideal for painted finishes. | Heavy and dense – More difficult to transport and install than plywood. |

| Uniform construction – No knots, cracks, or inconsistencies found in natural wood. | Less impact-resistant – Can dent or crack under heavy pressure. |

| Customizable – Can be cut into intricate designs without splintering. | Difficult to repair – Damaged areas do not sand well and may require full replacement. |

| Stable in dry conditions – Does not expand or contract with temperature changes. | Weaker screw-holding ability – Screws can loosen over time, requiring special fasteners. |

| Reduces wood waste – Made from recycled wood fibers, which helps conserve natural resources. | Some types contain VOCs – Certain MDF products release formaldehyde, though low-VOC and CARB-compliant options are available. |

| Available in specialty types – Moisture-resistant, fire-retardant, and lightweight options offer more versatility. | Cannot be stained – Unlike natural wood, MDF does not absorb stain well and must be painted or laminated. |

How Long Do MDF Kitchen Cabinets Last?

MDF kitchen cabinets typically last 15 to 25 years, depending on material quality, construction, and maintenance. Some manufacturers estimate a 20-year lifespan, though well-maintained MDF can last longer. Moisture is the primary threat to durability. If properly sealed and kept dry, MDF cabinets hold up as well as many solid wood alternatives.

Proper care prevents premature damage. Below, we’ve laid out some maintenance tips to keep your MDF cabinets lasting longer:

- High-quality paints and sealants protect against moisture absorption.

- Immediate cleanup of spills reduces the risk of swelling or warping.

- Soft-close hinges prevent stress cracks from repeated slamming.

- Furniture pads reduce impact damage.

- Regular dusting with a soft, lint-free cloth keeps the surface clean without causing scratches.

- Avoid abrasive cleaners or harsh chemicals, as they can break down the finish.

How Much Do MDF Cabinets Cost?

MDF kitchen cabinets typically cost between $150 and $300 per linear foot, depending on design complexity, finish, and customization. Prefabricated MDF cabinets fall on the lower end of this range, while custom-built options with intricate detailing and premium finishes push costs higher.

For an average-sized kitchen of 10×10 feet, stock MDF cabinets range from $3,000 to $6,000, while semi-custom versions cost $6,000 to $12,000. Custom MDF cabinetry, which includes personalized designs and high-end coatings, can exceed $15,000. Installation costs vary but generally add $50 to $100 per linear foot, depending on labor rates and project complexity.

Thermofoil MDF cabinets, which have a vinyl coating for added durability, cost slightly more at $200 to $350 per linear foot. High-gloss or specialty-painted MDF increases pricing due to the additional finishing process.

At Seattle Cabinets, we offer high-quality custom cabinetry starting at $2,500. We accommodate projects of all sizes and design preferences, manufacturing everything in-house at our Seattle warehouse. We also provide professional installation services, ensuring a seamless fit and finish.

Are MDF Kitchen Cabinets Right For You?

MDF kitchen cabinets offer a cost-effective alternative to solid wood, providing a smooth, paintable surface with a wide range of customization options. While they are more stable than natural wood in dry conditions, they require proper sealing and maintenance to prevent moisture damage. For homeowners in humid environments, moisture-resistant MDF improves durability and lifespan.

Choosing the right cabinets depends on budget, style, and long-term maintenance expectations. MDF works best for painted cabinetry and modern designs, but solid wood or plywood may be better suited for areas exposed to high humidity and heavy use.

At Seattle Cabinets, we build custom kitchen and bathroom cabinetry in our Seattle-based workshop, giving us full control over quality, materials, and craftsmanship. This allows us to meet the highest standards of manufacturing and offer more competitive pricing by eliminating middlemen and passing the savings directly to our clients. Get in touch with us to learn more about MDF and other cabinetry options that match your style and functional needs. Get started with a free design consultation today. Call (206) 360-9090 or visit Seattle Cabinets to explore your options!